Simpson Strong Tie Flat Strap

Simpson Strong-Tie Flat Strap – 1200 x 30mm

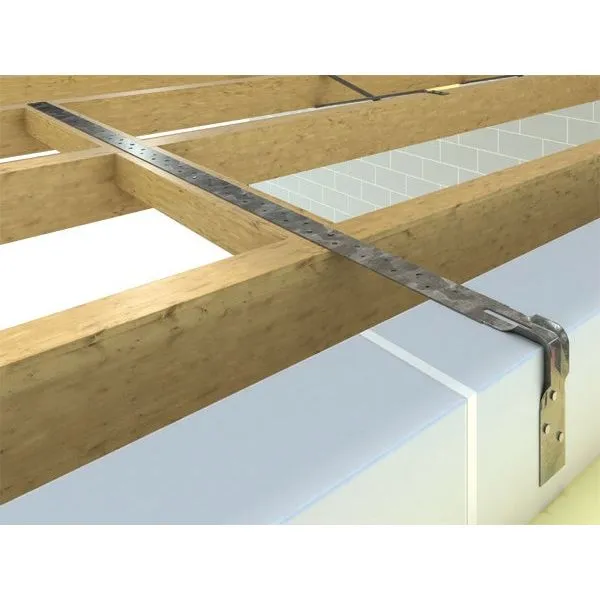

Versatile Restraint Straps for Timber-to-Masonry Connections

Overview

The Simpson Strong-Tie Flat Strap 1200mm is a high-quality structural restraint strap used to ensure secure lateral or vertical connection between timber framing components (like joists, trusses, or wall plates) and masonry walls. Available in both light duty (2.5mm thick) and heavy duty (5mm thick) variations, this product complies with UK Building Regulations, BS 5268 Part 3, and other key structural standards.

These restraint straps are suitable for use in a wide range of residential, commercial, and industrial construction applications. Their robust yet lightweight design offers excellent handling and performance during installation.

Product Variants

Flat Strap 1200 x 30 x 2.5mm (Light Restraint Strap)

Flat Strap 1200 x 30 x 5mm (Heavy Restraint Strap)

Key Features (All Variants)

-

Conforms to Building Regulations

Designed and manufactured in accordance with BS 5268 Part 3, and approved by NHBC for use as an alternative to traditional restraint strapping.

-

High-Strength Galvanised Steel

Manufactured using mild steel to BS EN 10327:2004 DX51D+Z275, with Z275/Z300 pre-galvanised coating, offering superior corrosion protection for long-term durability.

-

Flat Face Rolled Form Design

Optimised for strength and ease of installation. The rolled form makes it lighter to handle while maintaining excellent performance in structural applications.

-

Versatile Applications

Suitable for both vertical and horizontal restraint, connecting timber to masonry in both new builds and refurbishment projects.

-

Available in All Common Lengths

Supplied in standard sizes ranging from 500mm to 2000mm in 100mm increments for convenient use in all construction scenarios.

-

Meets Cavity Wall Tie Requirements

HTFA and LTFA versions are specially designed to bridge 50mm cavities, extending 75mm into brickwork and 300mm into the timber frame.

Materials & Finishes

| Type |

Thickness |

Coating |

Application |

| H / HTFA |

30mm x 5mm |

Z300 Galvanised |

Heavy duty, lateral restraint |

| L / LTFA |

30mm x 2.5mm |

Z300 Galvanised |

Light duty, vertical restraint |

| HRS |

30mm x 1.5mm |

Z275 Galvanised |

Rolled form, NHBC approved alternative |

| LRS |

30mm x 1.0mm |

Z275 Galvanised |

Lightweight rolled form |

Installation Guidance

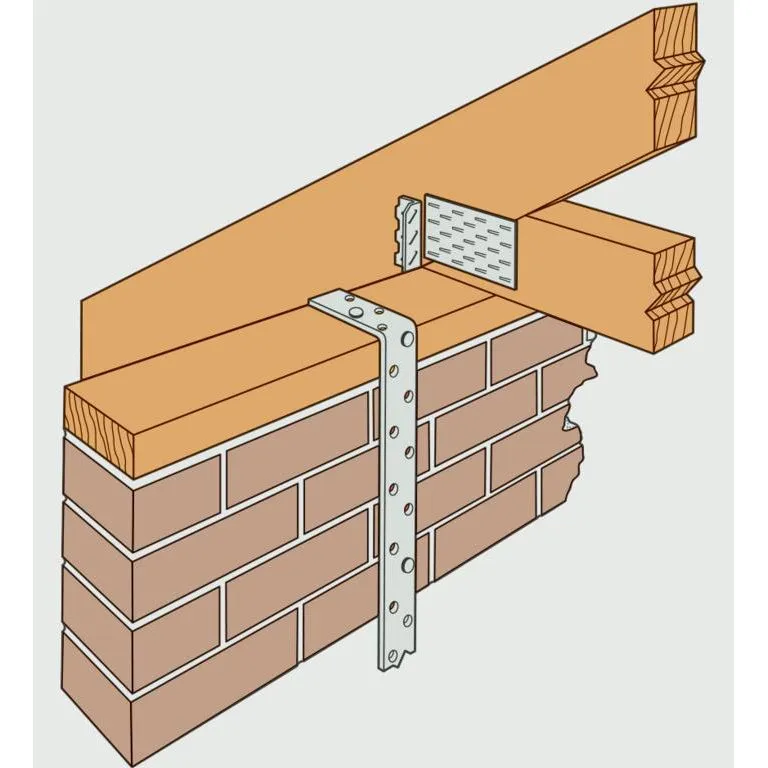

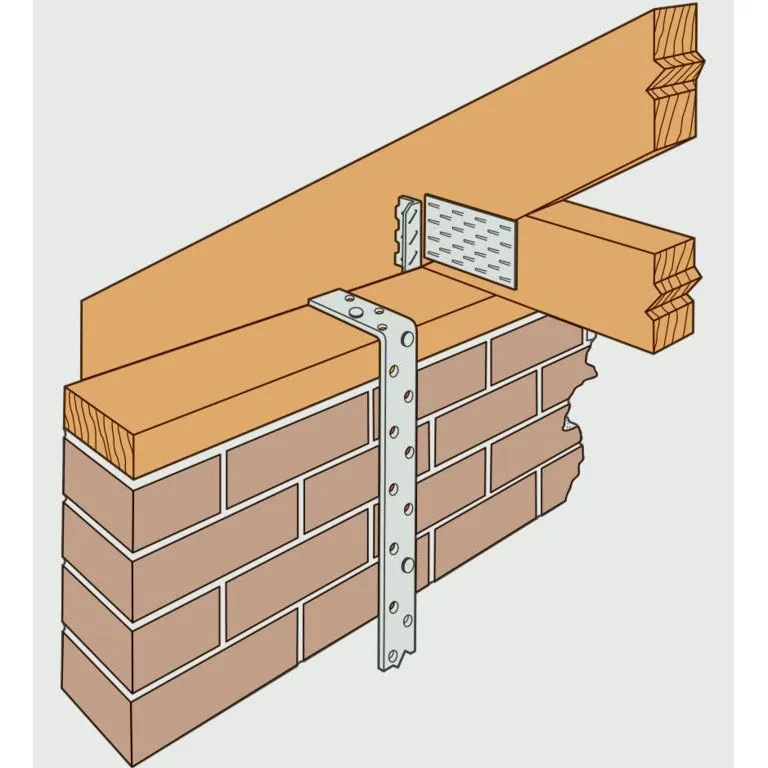

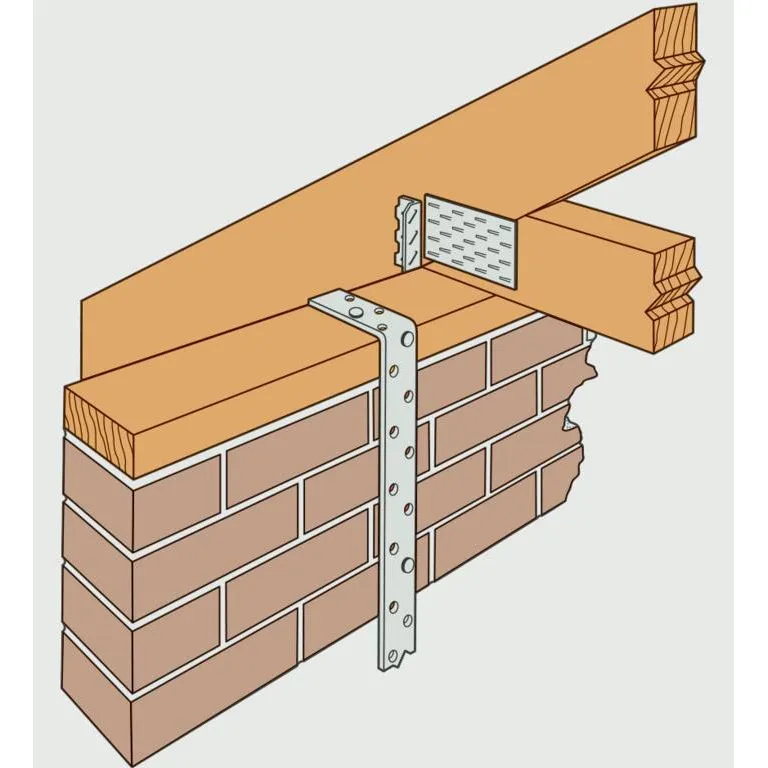

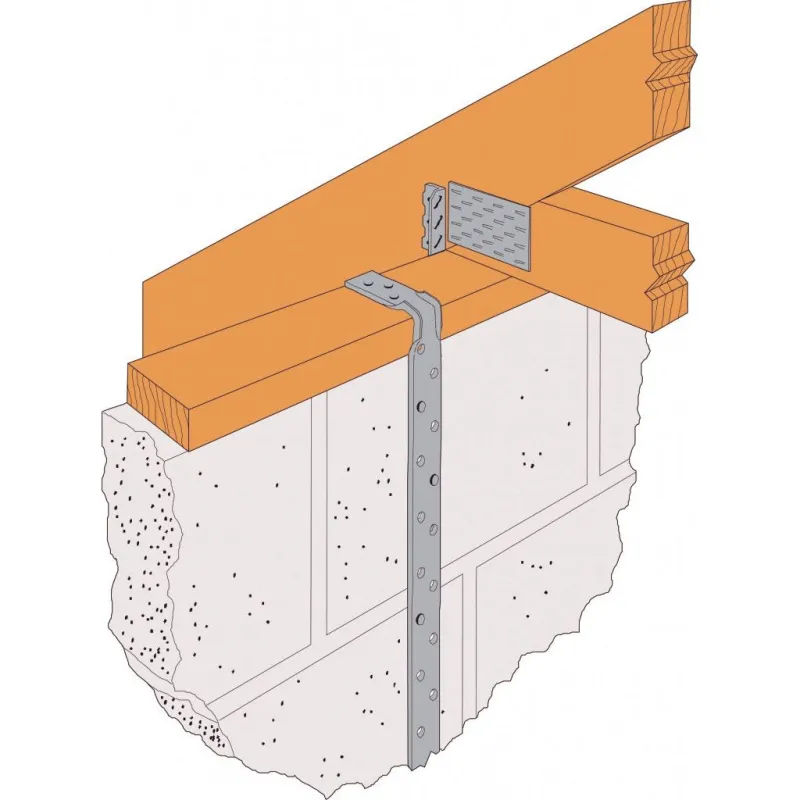

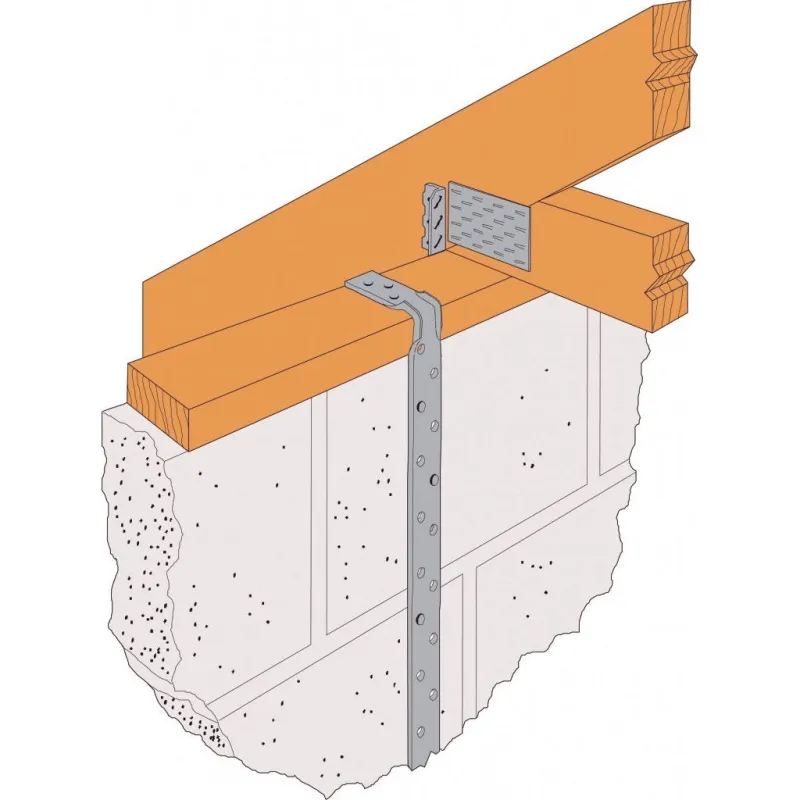

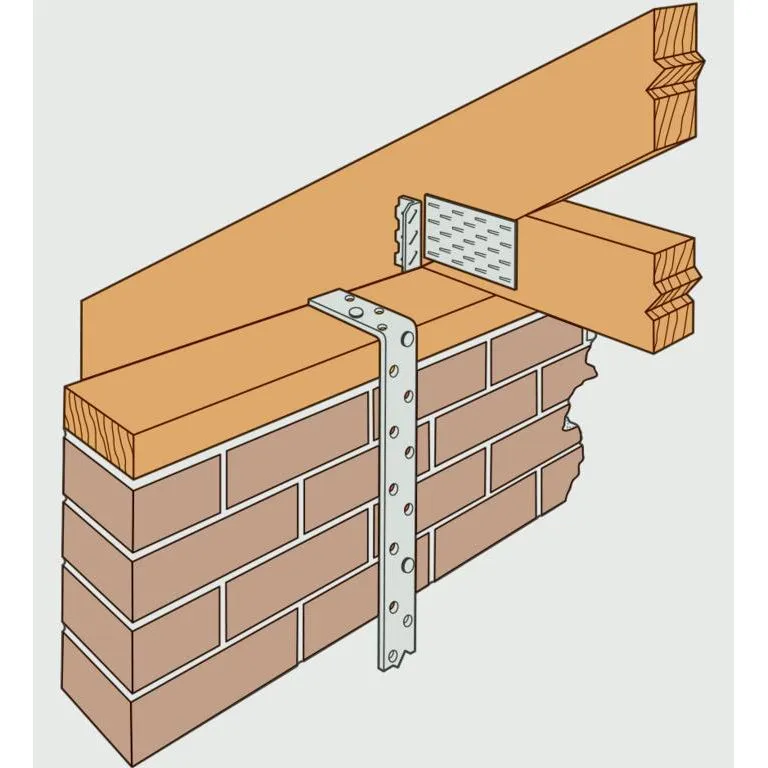

Horizontal Installation (Lateral Restraint)

-

Straps must be positioned no more than 2m apart.

-

Must be fixed across at least 3 timber members using noggings and packers.

-

Secure to timber with:

-

Minimum bend length into masonry should be 100mm, positioned in the centre of an uncut brick/block.

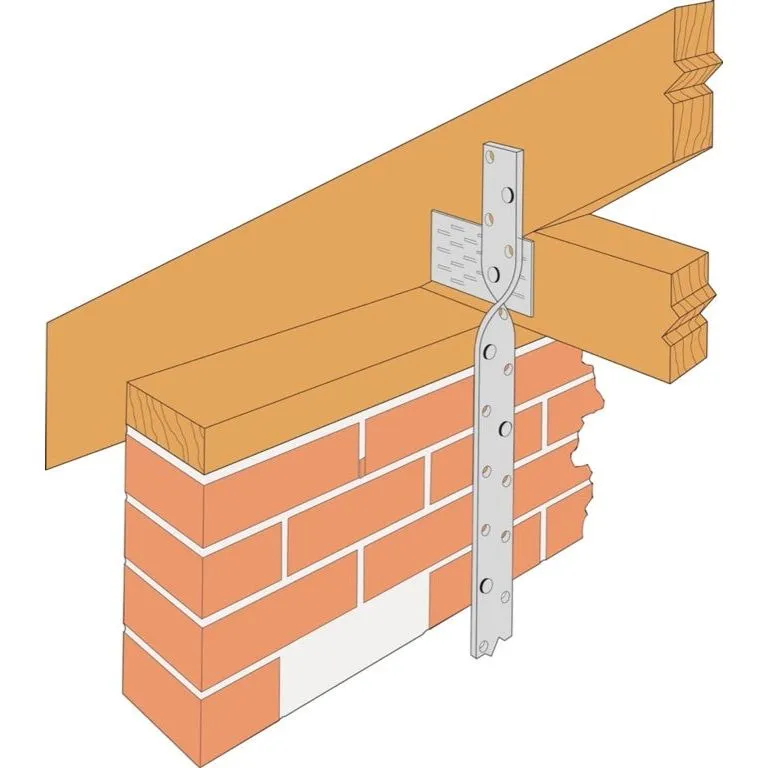

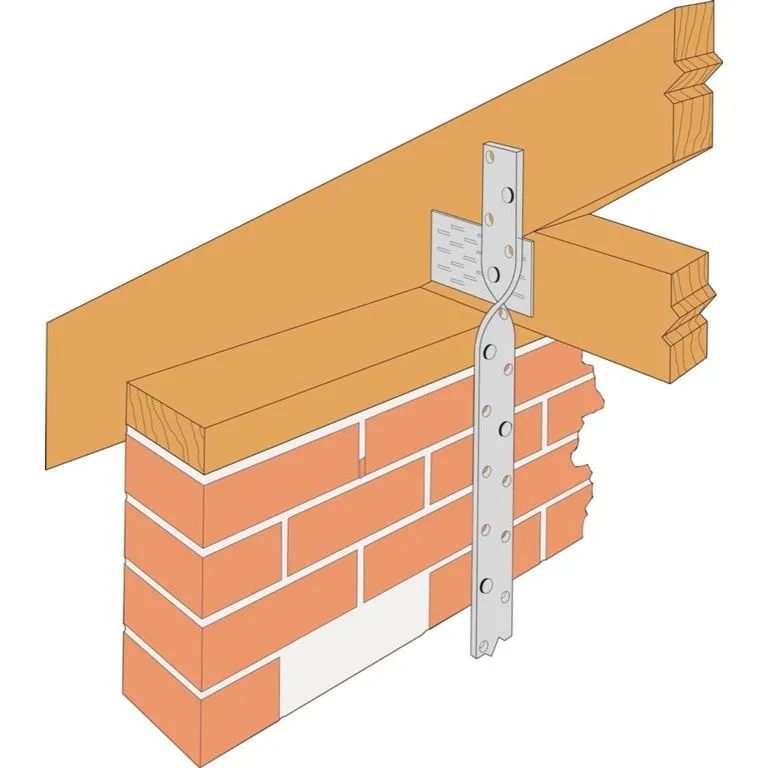

Vertical Installation (Wall Plate Restraint)

-

Strap should be at least 1 metre long.

-

Secure to masonry using:

-

The lowest fixing point must be no more than 150mm from the base of the strap.

-

Ensure the flat face of the strap is flush against the timber.

Typical Applications

-

Lateral restraint of roof trusses, rafters, and floor joists to masonry

-

Vertical restraint of wall plates and timber frames

-

Cavity wall bridging (HTFA/LTFA types)

-

Timber-to-masonry connection in timber frame construction

-

Retrofit structural reinforcement in domestic and commercial buildings

Benefits

-

Strong, reliable timber-to-masonry connection

-

Lightweight for easier handling on-site

-

Fully compliant with UK building codes

-

Fast installation with standard tools

-

Approved alternative to traditional flat strapping

-

Resistant to rust and weathering

Frequently Asked Questions (FAQ)

Q1: What’s the difference between light and heavy restraint straps?

A: Light restraint straps (30 x 2.5mm) are typically used for vertical applications, such as restraining wall plates. Heavy restraint straps (30 x 5mm) are designed for horizontal loads, like securing floor joists and roof structures to masonry.

Q2: Can these straps be used in cavity wall construction?

A: Yes. The HTFA and LTFA models are designed specifically to bridge 50mm cavities, extending into both brickwork and timber frame, making them suitable for cavity wall installations.

Q3: Do these straps require any special tools?

A: No. Installation can be done using standard screws or nails and basic hand tools (screwdriver, drill, or hammer). However, correct spacing and fixing per regulations must be followed for safety and compliance.

Q4: Are the straps weather-resistant?

A: Yes. The straps are pre-galvanised to resist corrosion, making them suitable for use in sheltered outdoor and all indoor environments.

Q5: How many straps do I need for a floor or roof section?

A: As a general rule, horizontal straps should be installed every 2 metres, fixing to a minimum of 3 joists or trusses. Vertical straps should be at least 1m long and securely anchored to masonry with appropriate fixings.

Q6: Can these straps be used in NHBC-approved builds?

A: Yes. The HRS (30 x 1.5mm) is accepted by the NHBC as an alternative to the traditional 30mm x 5mm strapping, offering equivalent performance with reduced weight.

Conclusion

The Simpson Strong-Tie Flat Strap 1200 x 30mm range offers a versatile, code-compliant solution for a wide range of structural restraint applications. Whether you need lightweight vertical restraint or robust lateral connection, these straps deliver outstanding reliability and ease of installation. Backed by Simpson Strong-Tie’s engineering expertise, they are trusted by professionals across the construction industry.

Smiths Architectural Lunar Handle Latch Pack CP 52mm rose dia.

1 × £8.39

Smiths Architectural Lunar Handle Latch Pack CP 52mm rose dia.

1 × £8.39  Bentley Deluxe Hinge Mop Refill

1 × £1.80

Bentley Deluxe Hinge Mop Refill

1 × £1.80  Bayport 1200mm Sliding Door & 800mm Tray Pack - Chrome

1 × £81.45

Bayport 1200mm Sliding Door & 800mm Tray Pack - Chrome

1 × £81.45  Araldite Precision Syringe

1 × £3.99

Araldite Precision Syringe

1 × £3.99  Tala Performance Stainless Steel Soup Spoons Set 4

1 × £2.85

Tala Performance Stainless Steel Soup Spoons Set 4

1 × £2.85  Standing Reindeer With Lights Berry Twig And Glitter Decoration For Indoor Use

1 × £17.99

Standing Reindeer With Lights Berry Twig And Glitter Decoration For Indoor Use

1 × £17.99  Oust All Purpose Descaler Bottle

1 × £1.41

Oust All Purpose Descaler Bottle

1 × £1.41  Nimbus Rice Pasta Plate 26cm

1 × £3.22

Nimbus Rice Pasta Plate 26cm

1 × £3.22  Primeur Flexi Curve Border Rockwall Earth 5x9x122cm

1 × £8.69

Primeur Flexi Curve Border Rockwall Earth 5x9x122cm

1 × £8.69  Petit Chrome Bath Filler

1 × £44.36

Petit Chrome Bath Filler

1 × £44.36  Astor 8 Person Rectangle Dining Set

1 × £123.99

Astor 8 Person Rectangle Dining Set

1 × £123.99  Securit Brass Numeral No.5

1 × £0.97

Securit Brass Numeral No.5

1 × £0.97  Pound Thru' Soft Grip Screwdriver Set (6 Piece)

1 × £16.36

Pound Thru' Soft Grip Screwdriver Set (6 Piece)

1 × £16.36