Securplumb SR61 Stop End Solder Ring

Securplumb SR61 Stop End Solder Ring – 15mm & 22mm (Pack of 10) – Professional Pipe Termination Solution

The Securplumb SR61 Stop End Solder Ring is a precision-engineered plumbing fitting used to seal the end of copper pipework. Designed with a factory-applied solder ring, this fitting delivers a clean, strong, and watertight connection without the need for additional soldering material. Ideal for terminating unused pipe ends, isolating sections of a system, or preparing pipework for future extensions, this fitting is an indispensable part of any professional plumber’s toolkit.

Available in two popular sizes—15mm and 22mm—and sold in packs of 10, the SR61 is ideal for both small-scale domestic plumbing and larger commercial installations. Whether you’re upgrading, repairing, or capping off new pipework, the SR61 offers simplicity, safety, and long-lasting performance.

Product Variants and Packaging

Key Features

-

Pre-Loaded Solder Ring: Each fitting comes with a precision-applied ring of solder that melts upon heating, ensuring a consistent, high-quality seal every time. This eliminates the need for loose solder, making installation quicker and cleaner.

-

High-Quality Material: Manufactured from premium-grade copper alloy, these stop ends provide excellent corrosion resistance and long-term durability in both hot and cold water systems.

-

Leak-Free Performance: Designed for reliability, the stop end ensures a secure and watertight seal, preventing drips, pressure loss, or water damage.

-

Versatile Use: Suitable for use in domestic, commercial, and industrial plumbing applications, including central heating systems, potable water lines, and isolated pipe branches.

-

Convenient Quantity: Pack of 10 fittings offers cost-efficiency and convenience for larger jobs, reducing the need for multiple purchases and ensuring consistency across installations.

Applications

-

Capping off unused copper pipe runs

-

Isolating sections of pipework during system extensions or maintenance

-

Terminating dead legs or future connection points

-

Sealing ends of supply pipes in renovation or new build projects

-

Used in both pressurized and gravity-fed water systems

Installation Instructions

-

Prepare the Pipe: Use a pipe cutter to achieve a clean, square cut on the copper pipe. Remove any burrs using a deburring tool.

-

Clean Surfaces: Use emery cloth or a pipe cleaning brush to clean both the outer surface of the pipe and the inside of the stop end fitting. This helps ensure optimal solder adhesion.

-

Apply Flux: Although the fitting includes pre-loaded solder, it is good practice to apply a thin, even layer of flux to the outside of the pipe to promote better solder flow.

-

Insert Pipe: Push the cleaned pipe fully into the stop end fitting until it meets the internal shoulder.

-

Heat the Joint: Use a propane or MAPP gas torch to apply heat evenly to the joint. The solder ring will melt and flow into the joint by capillary action, creating a strong bond.

-

Allow to Cool: Let the joint cool naturally without disturbing it to preserve the integrity of the seal.

-

Pressure Test: Once cooled, test the system under pressure to confirm that the joint is completely sealed and leak-free.

Care and Maintenance

-

Storage: Store in a clean, dry location away from corrosive environments to preserve the condition of the solder ring.

-

Handling: Avoid denting or deforming the fittings during transport or installation, as this may impair the effectiveness of the seal.

-

Cleaning: Prior to installation, remove any surface oxidation or contaminants that could affect soldering performance.

-

Inspection: Periodically inspect installed joints, especially in high-pressure or high-temperature systems, to ensure long-term reliability.

-

Replacement: Damaged or corroded fittings should be removed and replaced immediately to maintain system integrity and prevent water damage.

Frequently Asked Questions (FAQ)

Is the stop end suitable for both hot and cold water systems?

Yes, the SR61 Stop End Solder Ring is suitable for use in both hot and cold potable water systems, as well as central heating systems.

Can I use these for pressurized systems?

Absolutely. When installed correctly, the soldered joint will provide a strong and pressure-resistant seal suitable for pressurized water and heating systems.

Is additional solder required?

No. The stop end is pre-loaded with solder. However, the use of flux is still recommended to promote even solder flow and ensure a fully sealed joint.

Are these WRAS approved?

Securplumb fittings are manufactured to meet UK plumbing standards. For specific WRAS certification, consult with your supplier.

Can these be installed by a DIYer?

Yes, individuals with basic plumbing knowledge and access to a suitable gas torch can install these fittings. However, professional installation is advised for critical or high-pressure systems to ensure full compliance with plumbing regulations.

Why Choose the Securplumb SR61 Stop End Solder Ring?

The Securplumb SR61 Stop End Solder Ring offers a quick, dependable, and cost-effective solution for terminating copper pipework with minimal effort. Its pre-soldered design reduces installation time while maintaining a strong, professional seal. With its corrosion-resistant material, precision fit, and availability in two popular sizes, it’s the ideal choice for any plumber or contractor working on domestic or commercial water systems.

Choose the Securplumb SR61 Stop End Solder Ring – the efficient and professional way to end your pipework safely and securely.

Washing Brush Rigid (Basic)

1 × £4.14

Washing Brush Rigid (Basic)

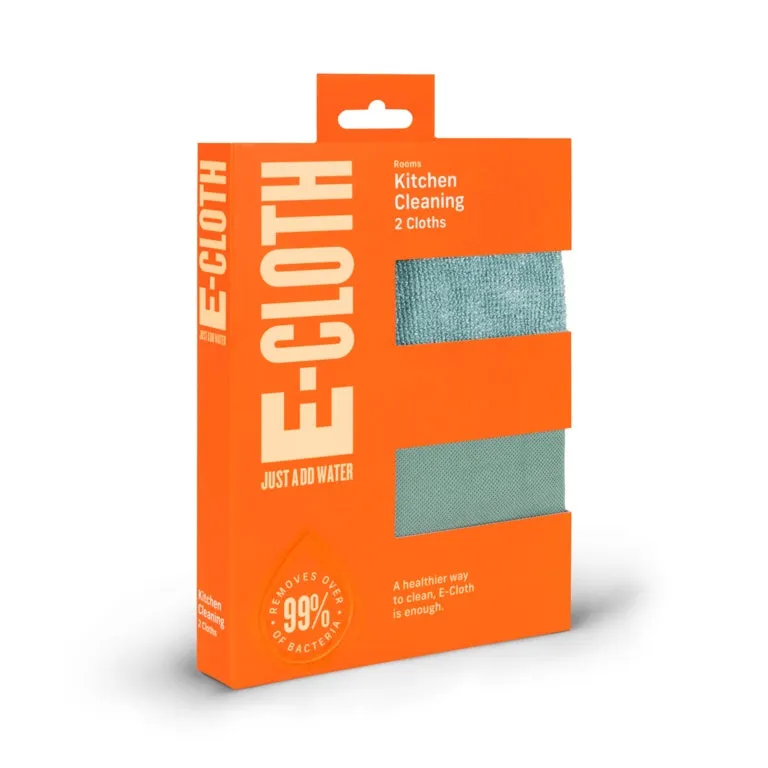

1 × £4.14  E-Cloth Kitchen Pack – 2 Cloth Set for Effortless Cleaning

1 × £5.67

E-Cloth Kitchen Pack – 2 Cloth Set for Effortless Cleaning

1 × £5.67  Patterned Chrome Radiator Valves - Corner

1 × £19.80

Patterned Chrome Radiator Valves - Corner

1 × £19.80  Ronseal Decking Cleaner & Reviver

1 × £8.09

Ronseal Decking Cleaner & Reviver

1 × £8.09  Fast Pak 1 1/16'' HOSE CLIPS

1 × £0.75

Fast Pak 1 1/16'' HOSE CLIPS

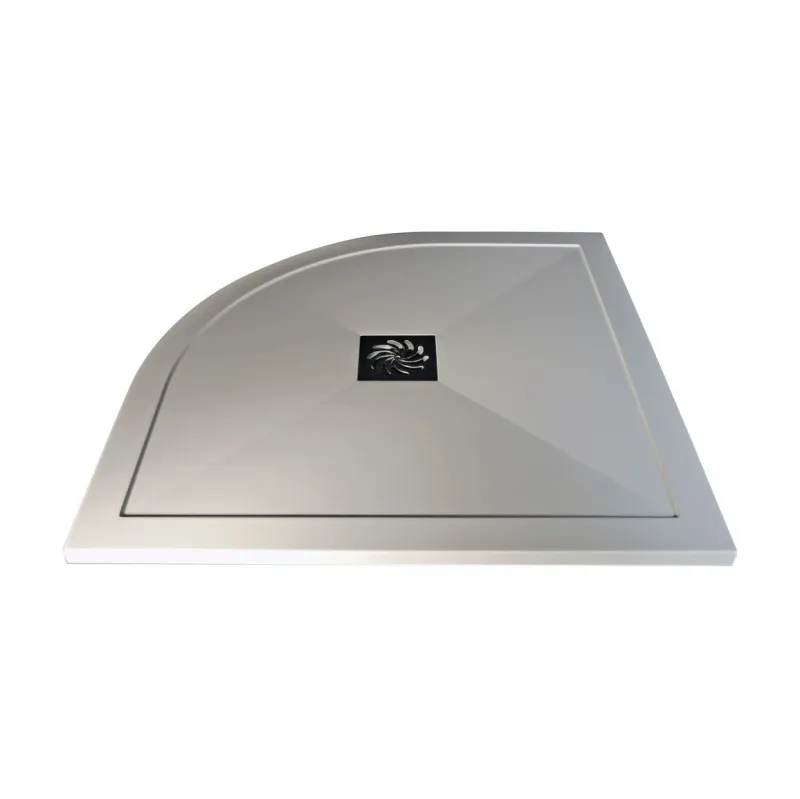

1 × £0.75  25mm Ultra-Slim 900mm x 900mm Quadrant Tray & Waste

1 × £87.97

25mm Ultra-Slim 900mm x 900mm Quadrant Tray & Waste

1 × £87.97  Black & Decker 400W Scorpion® Powered Handsaw

1 × £24.20

Black & Decker 400W Scorpion® Powered Handsaw

1 × £24.20  Oracstar Pre Soldered Angled Tap Connector

1 × £3.38

Oracstar Pre Soldered Angled Tap Connector

1 × £3.38