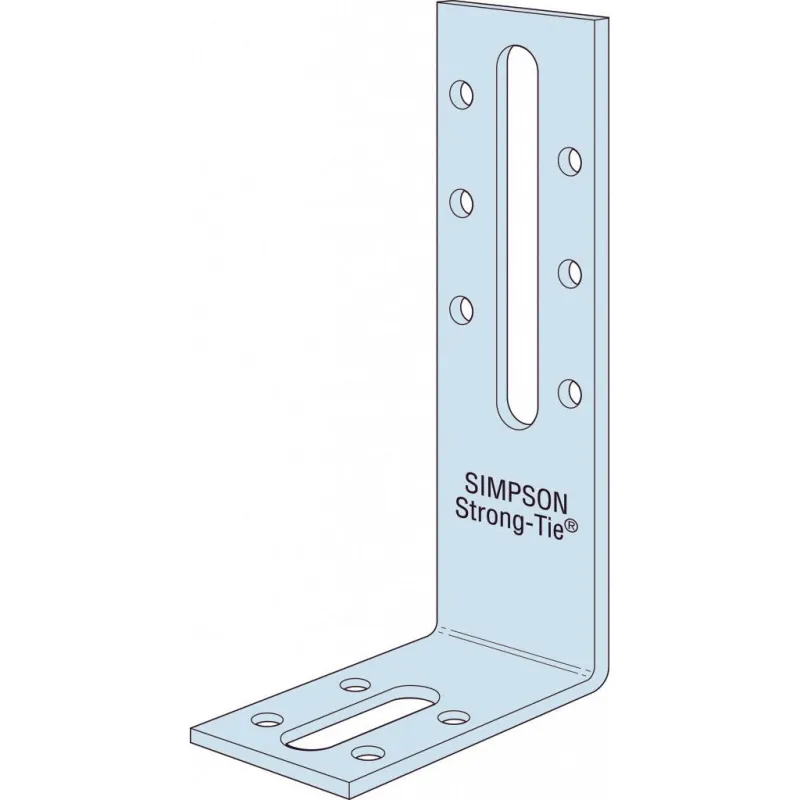

Simpson Strong Tie Adjustable Angle Bracket

Simpson Strong Tie Adjustable Angle Bracket

Heavy-Duty, Versatile, and Fully Adjustable Fixing Solution for Structural and Assembly Applications

Product Description

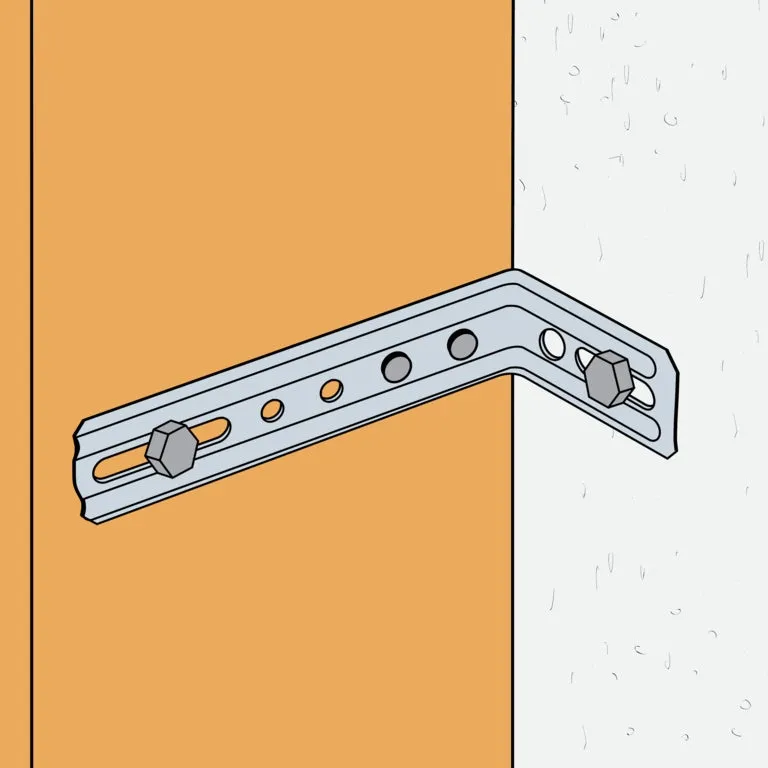

The Simpson Strong Tie Adjustable Angle Bracket is engineered to deliver both strength and flexibility in a wide variety of fixing and structural reinforcement tasks. Manufactured from high-quality pre-galvanised mild steel, these brackets combine robust mechanical properties with excellent corrosion resistance, ensuring longevity and reliable performance even under challenging installation environments.

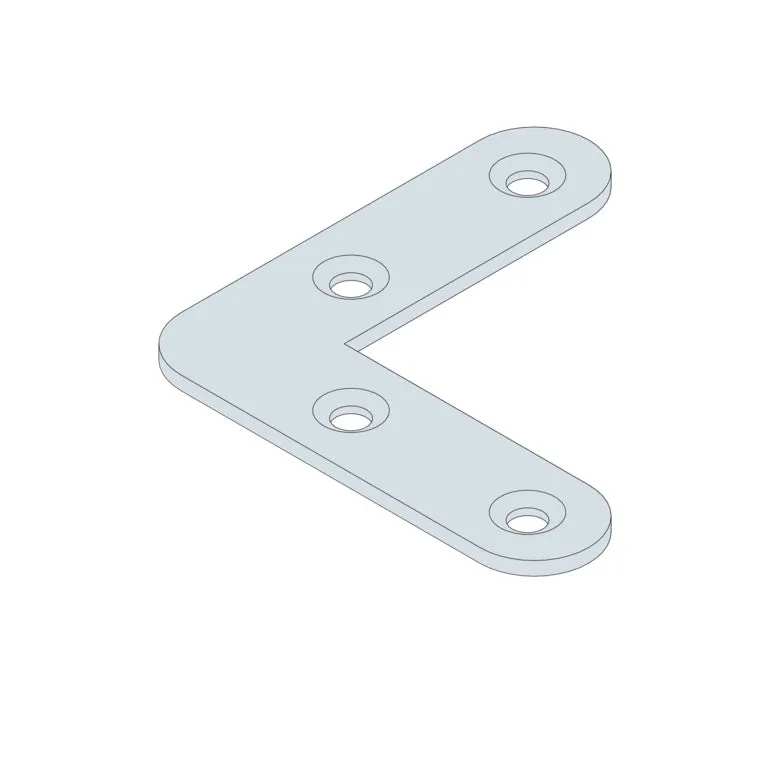

What sets these brackets apart is their adjustability—featuring obround (elongated) slots rather than fixed circular holes. This design innovation enables installers to adjust the position of the bracket after initial fixing, allowing for precise alignment and positioning, reducing installation time and errors.

The bracket is supplied in two common sizes, each designed to meet different load and spatial requirements. Both feature a sturdy right-angle design with reinforced elements to enhance load capacity and resist deformation under stress.

Technical Specifications

| Feature |

Adjustable Angle Bracket 70 x 50 x 30 mm |

Adjustable Angle Bracket 98 x 52 x 30 mm |

| Boxed Weight |

45 grams |

Not specified (typically around 80-100g) |

| Material |

Pre-galvanised mild steel |

Pre-galvanised mild steel |

| Finish |

Zinc-coated for corrosion resistance |

Zinc-coated for corrosion resistance |

| Bracket Dimensions |

70 mm (height) x 50 mm (width) x 30 mm (depth) |

98 mm (height) x 52 mm (width) x 30 mm (depth) |

| Thickness |

Approx. 1.5 – 2 mm (typical mild steel gauge) |

Approx. 1.5 – 2 mm (typical mild steel gauge) |

| Hole Type |

Obround slots (elongated holes) for adjustability |

Two obround holes for easier alignment |

| Reinforcement |

Reinforced stiffener for enhanced strength |

No stiffener but strong construction |

| Load Capacity |

Suitable for light to medium duty connections |

Suitable for medium duty connections |

Key Features and Benefits

1. Adjustable Obround Slots for Precision Installation

Unlike fixed-hole brackets, these adjustable brackets incorporate obround slots which enable lateral or longitudinal movement of the bracket relative to the fixing point during installation. This flexibility:

-

Ensures exact alignment with mating surfaces or components

-

Accommodates dimensional tolerances in timber, metal, concrete, or PVC substrates

-

Reduces installation time by allowing positioning adjustments without removing and redrilling fixings

-

Minimizes material wastage by avoiding rework or damaged components

2. Robust Pre-Galvanised Mild Steel Construction

Manufactured from pre-galvanised mild steel, these brackets provide:

-

Corrosion resistance for indoor use and sheltered outdoor applications

-

High tensile strength to withstand stresses from lateral and vertical loads

-

Durability and longevity ensuring the bracket maintains integrity over time

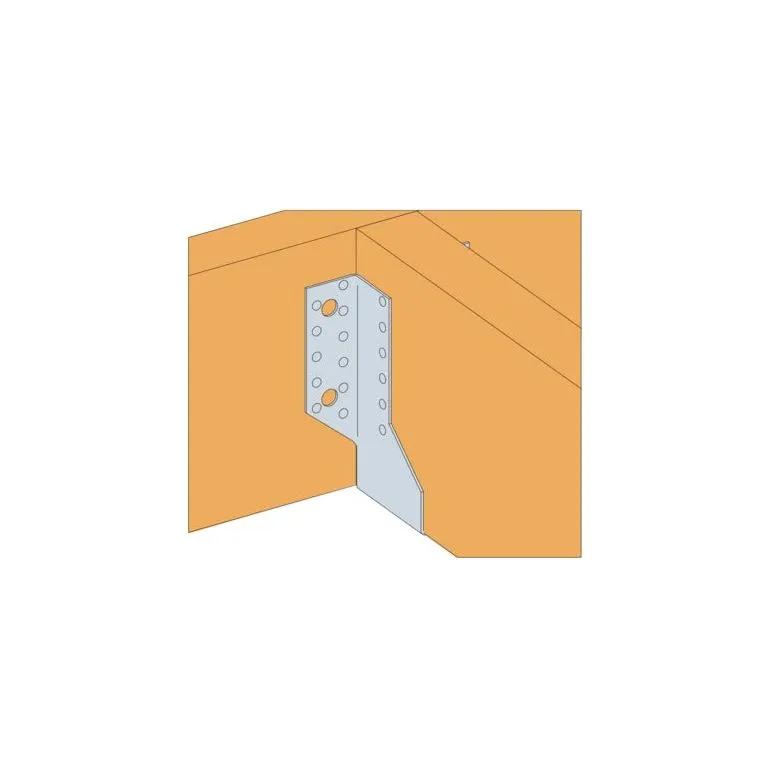

3. Reinforced Stiffener (70 x 50 x 30 mm model)

The smaller bracket includes an integrated stiffener bar that increases resistance to bending or twisting under load, making it especially suitable for applications where additional rigidity is required but space is limited.

4. Multi-Substrate Compatibility

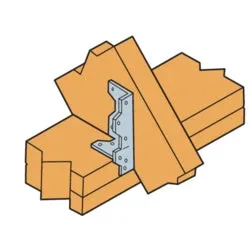

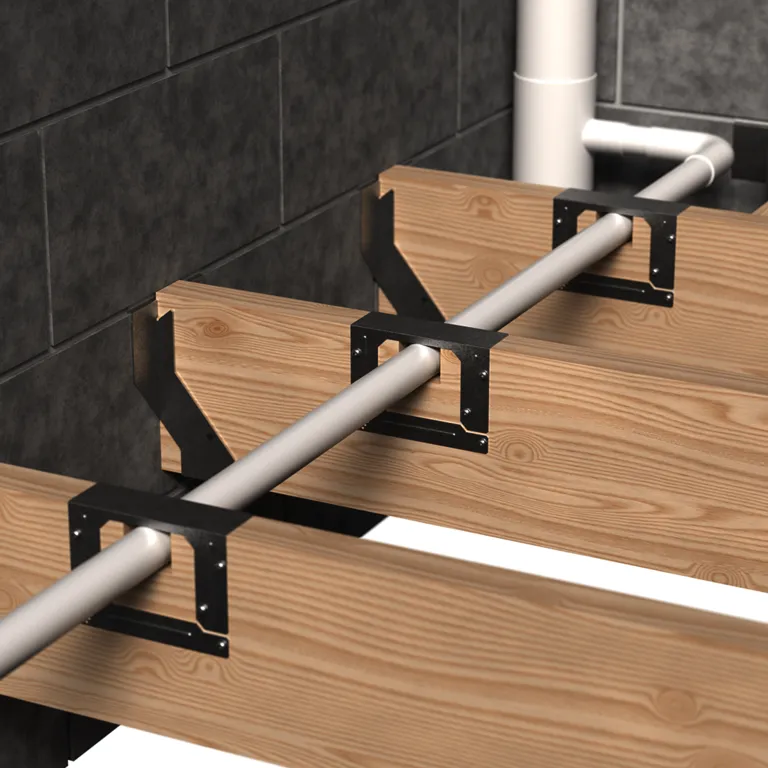

Designed for universal use, these brackets can be fastened securely to a variety of substrates:

-

Wood — ideal for timber framing, furniture assembly, or cabinetry

-

Concrete and masonry — suitable for connecting metal or timber components to concrete walls or floors

-

Metal — useful for structural steel reinforcement or lightweight metal framing

-

PVC and composites — applicable in plastic framing and construction where metal-to-plastic joins are needed

5. Wide Range of Applications

These adjustable brackets are suitable for an extensive range of uses:

-

Structural framing in residential and commercial buildings

-

Furniture and cabinetry construction requiring strong, adjustable connections

-

Storage racks, shelving units, and frames where precise positioning is critical

-

Window and door frame reinforcement

-

DIY projects and repair work where adaptable brackets save time and improve accuracy

6. Ease of Installation

The obround slots simplify alignment during installation and allow for quick, accurate adjustments after fixing the first fastener. This eliminates the need for repeated drilling or repositioning, reducing labor costs and installation complexity.

Installation Instructions

-

Preparation

-

Select an appropriate bracket size based on load requirements and space constraints.

-

Choose fasteners compatible with the substrate material (e.g., wood screws, masonry anchors, machine bolts).

-

Mark fixing points on the structure or assembly where the bracket will be attached.

-

Positioning

-

Place the bracket at the approximate location.

-

Insert fixings loosely through the obround slots, allowing the bracket to slide.

-

Adjustment

-

Securing

-

Tighten all fixings firmly, ensuring the bracket is securely anchored and cannot move.

-

Check for stability and ensure no gaps exist between the bracket and the substrate.

-

Final Check

Material and Finish Details

-

Mild Steel to BS EN 10327:2004 — ensures compliance with European standards for structural steel products.

-

Pre-Galvanised Finish (Z275 or Z300 coating) — provides a zinc coating to prevent corrosion and rust formation, enhancing durability in typical environmental conditions.

-

Edge-Coated — the edges of the steel are coated to protect cut surfaces from corrosion.

Frequently Asked Questions (FAQ)

Q1: What are obround holes and why are they important?

A: Obround holes are elongated holes that allow for adjustment of the bracket position after partial fixing. This is important for precise alignment, accommodating structural tolerances, and simplifying installation.

Q2: Can the brackets be used outdoors?

A: Yes, but with limitations. The pre-galvanised finish offers corrosion resistance suitable for indoor and some sheltered outdoor environments. For harsh or exposed outdoor conditions, additional protection or stainless steel alternatives should be considered.

Q3: How do I choose the right size bracket?

A: The choice depends on the load requirements, available space, and substrate. The 70 x 50 x 30 mm bracket is lighter duty with added stiffener, suitable for smaller assemblies. The 98 x 52 x 30 mm bracket is larger and suitable for moderate load applications.

Q4: What types of fasteners should be used?

A: Use fasteners compatible with the substrate: wood screws for timber, anchors or plugs with masonry screws for concrete, and bolts or machine screws for metal. Always follow design and safety standards.

Q5: Are these brackets suitable for seismic or high-stress applications?

A: These are primarily designed for general structural reinforcement and assembly. For high-stress or seismic conditions, consult structural engineers and use products specifically certified for those applications.

Summary

The Simpson Strong Tie Adjustable Angle Bracket is a versatile, strong, and user-friendly fixing solution designed to improve installation accuracy and structural reliability. Its pre-galvanised steel construction provides lasting durability, while obround slots enable flexible positioning to meet the needs of a wide range of construction, carpentry, and DIY projects.

Whether you are reinforcing furniture joints, assembling frames, or connecting timber to masonry or metal, these adjustable brackets simplify your workflow and deliver professional results with confidence.

RJM Ladies Twist Yarn Chenille Hat With Pompom

1 × £2.70

RJM Ladies Twist Yarn Chenille Hat With Pompom

1 × £2.70  Oracstar Syphon Diaphagm Washers

1 × £0.56

Oracstar Syphon Diaphagm Washers

1 × £0.56  Securplumb Washing Machine Waste Trap 1 Spigot 40 x 75mm

1 × £2.84

Securplumb Washing Machine Waste Trap 1 Spigot 40 x 75mm

1 × £2.84  SupaGarden Giant Parasol Cover 190cm x 40cm x 25cm

1 × £1.90

SupaGarden Giant Parasol Cover 190cm x 40cm x 25cm

1 × £1.90  Qualtex Cooker Hood Grease Filters Red Line

1 × £1.67

Qualtex Cooker Hood Grease Filters Red Line

1 × £1.67  Zero In Household Pest Killer Sprayer 2L

1 × £8.69

Zero In Household Pest Killer Sprayer 2L

1 × £8.69  Zero In Fly Max XL Fly Catcher Refill (6 Sachet)

1 × £4.34

Zero In Fly Max XL Fly Catcher Refill (6 Sachet)

1 × £4.34  Tetrion Powerfil 600g

1 × £7.19

Tetrion Powerfil 600g

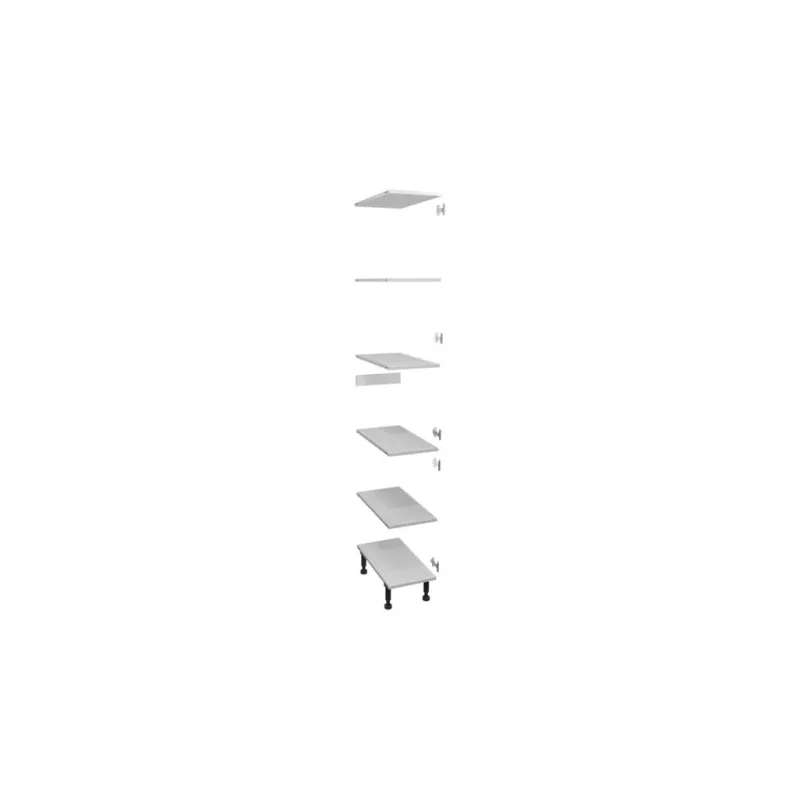

1 × £7.19  Gower Rapide+ Larder Unit Pack Shelves

1 × £54.00

Gower Rapide+ Larder Unit Pack Shelves

1 × £54.00  Rapide Rap Lime Hand Cleanser

1 × £0.68

Rapide Rap Lime Hand Cleanser

1 × £0.68  Securfix Heavy Duty Wall Plugs Brown

1 × £0.76

Securfix Heavy Duty Wall Plugs Brown

1 × £0.76  Ring H7 RU477 Headlamp

1 × £1.37

Ring H7 RU477 Headlamp

1 × £1.37  Securit Aluminium Face Fix Letter Plate

1 × £3.48

Securit Aluminium Face Fix Letter Plate

1 × £3.48  Picardy Arris Rail Bracket

1 × £0.46

Picardy Arris Rail Bracket

1 × £0.46  SupaTool Crocodile Clip Set

1 × £0.76

SupaTool Crocodile Clip Set

1 × £0.76  Rockwool Twin Roll 100mm x 2.75m x 1.2m (x 2) (6.60m2)

1 × £2.99

Rockwool Twin Roll 100mm x 2.75m x 1.2m (x 2) (6.60m2)

1 × £2.99  Clipper Fluid

1 × £1.19

Clipper Fluid

1 × £1.19  Bayport 700mm Side Panel - Chrome

1 × £50.20

Bayport 700mm Side Panel - Chrome

1 × £50.20  Mason Cash Botanical Gypsophila Stone Mug

1 × £2.38

Mason Cash Botanical Gypsophila Stone Mug

1 × £2.38  Classic 1500x330x22mm Laminate Worktop - Roma Marble Gloss

1 × £38.20

Classic 1500x330x22mm Laminate Worktop - Roma Marble Gloss

1 × £38.20  Tala Measuring Spoons, Plastic (Set of 6)

1 × £1.19

Tala Measuring Spoons, Plastic (Set of 6)

1 × £1.19  Castleview Paper Knives Pack 18

1 × £0.94

Castleview Paper Knives Pack 18

1 × £0.94  Recessed Manhole Cover Sealed And Locked 300 x 300 x 43.5mm

1 × £20.80

Recessed Manhole Cover Sealed And Locked 300 x 300 x 43.5mm

1 × £20.80  Easy Cook Large Sauce Pan & Lid

1 × £2.33

Easy Cook Large Sauce Pan & Lid

1 × £2.33  Vaillant EcoLevel Condensate Pump

1 × £73.02

Vaillant EcoLevel Condensate Pump

1 × £73.02  Fast Pak CURTAIN POLE RINGS 45mm SILVER

1 × £0.75

Fast Pak CURTAIN POLE RINGS 45mm SILVER

1 × £0.75  Ring Single Barrel Footpump

1 × £7.49

Ring Single Barrel Footpump

1 × £7.49  Vema Lys 4-Hole Deck Mounted Bath/Shower Mixer - Chrome

1 × £115.50

Vema Lys 4-Hole Deck Mounted Bath/Shower Mixer - Chrome

1 × £115.50  Luceco USB Folding Clamp Work Light

1 × £13.79

Luceco USB Folding Clamp Work Light

1 × £13.79  Fast Pak 1 3/4'' BATH/SINK PLUGS WHITE

1 × £0.75

Fast Pak 1 3/4'' BATH/SINK PLUGS WHITE

1 × £0.75  SupaPlumb Plug and Chain Basin Waste With Chrome Plug

1 × £4.47

SupaPlumb Plug and Chain Basin Waste With Chrome Plug

1 × £4.47  Sika 406 Stabilising Solution 5L

1 × £7.49

Sika 406 Stabilising Solution 5L

1 × £7.49  Pendeford Diamond Collection Non Stick Milk Pan 15cm

1 × £4.81

Pendeford Diamond Collection Non Stick Milk Pan 15cm

1 × £4.81  Securit Chrome Tube 19mm

1 × £2.36

Securit Chrome Tube 19mm

1 × £2.36